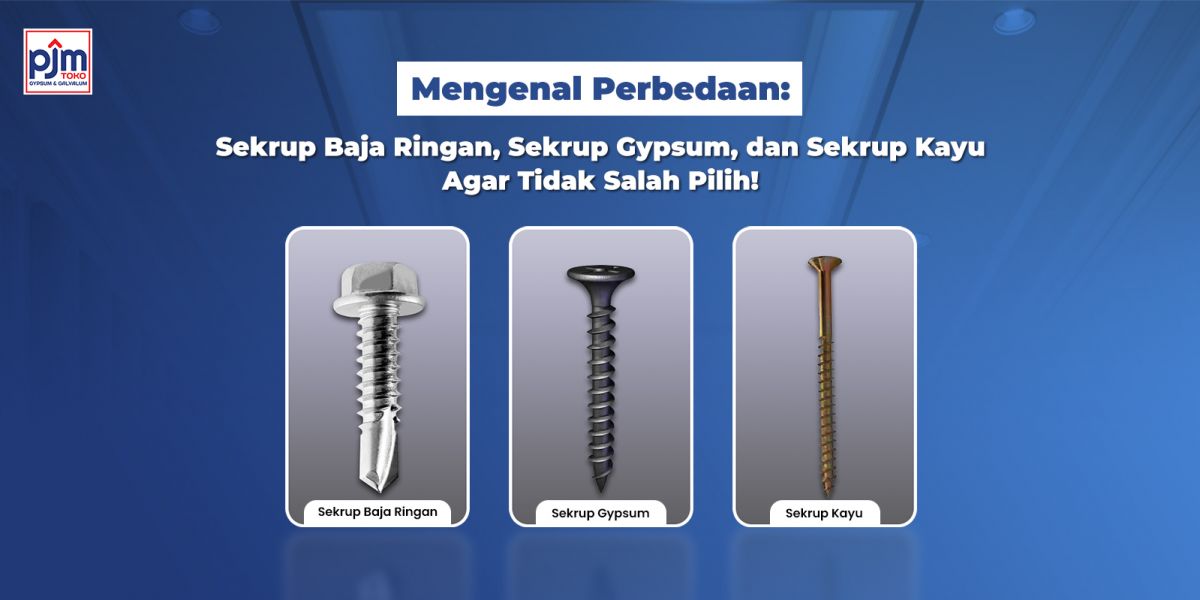

UNDERSTANDING THE DIFFERENCE BETWEEN SELF-TAPPING SCREWS FOR CONSTRUCTION

04 November 2025

For those of you often involved in the world of construction, as a builder, or in carpentry/furniture making, understanding the different types of screws is extremely important! Choosing the wrong screw can lead to suboptimal results—it can even cause the structural elements to deteriorate quickly.

In this article, PJM Store will explain the differences between the three most frequently used types of screws: lightweight steel screws, gypsum screws, and wood screws. Read on so you don't use the wrong one!

1. Lightweight Steel Screws

This type of screw is specially designed for joining or fastening lightweight steel frames. Its characteristic feature is a pointed, drill-like tip (self-drilling) that functions to penetrate the steel without the need for a pre-drilled hole.

In addition, the head of a lightweight steel screw is usually hex-shaped (six-sided) so it can be easily installed using an electric drill with a socket bit.

This screw is also coated with anti-rust material like zinc or galvanized steel, because lightweight steel is prone to corrosion if not protected.

- Main function: To unify joints in a lightweight steel frame without damaging the metal's protective layer. Do not use gypsum or wood screws for lightweight steel, as this can create a loose joint and risk rust.

2. Gypsum Screws

Gypsum screws are frequently used to attach gypsum board to either lightweight steel or wooden frames. Their distinguishing features are a trumpet-shaped head (flared like a funnel) and tight threads.

This design allows the screw to penetrate the gypsum board without tearing the surface, resulting in a neat finish that is easy to cover with putty before painting.

Gypsum screws are typically black, made of carbon steel, and come in various sizes depending on the thickness of the board and the frame.

- Main function: To firmly and evenly fasten gypsum board without damaging the surface.

- Pro Tip: Use a magnetic screwdriver or a drill at low speed so the screw head doesn't penetrate too deeply.

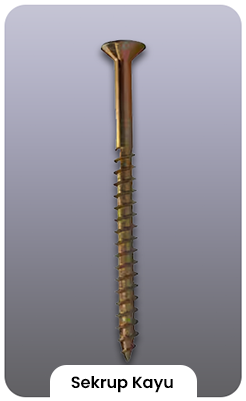

3. Wood Screws

Wood screws are the most classic and versatile type. They have a sharp tip with wide threads, suitable for penetrating wood fibers without causing cracks. The screw head is usually countersunk (tapering downwards) so that it sits flush with the wood surface once installed.

Besides being used for furniture, wood screws are often used for installing moldings, wooden ceilings, and various DIY projects around the house.

- Main function: To securely join two pieces of wood without damaging the fibers.

- Pro Tip: Choose a screw that is at least twice the thickness of the wood being joined for a sturdy result.

Although they may look similar, each screw has a different role and strength. Choosing the wrong type of screw can lead to weak joints, rapid rusting, or even damage to the material itself.

So, before starting your construction project, ensure you use the correct screw for its function and material. By doing so, your finished work will be stronger, tidier, and more durable!

Shop for Quality Screws at PJM Store!

If you need lightweight steel and gypsum screws with the best quality and friendly prices, head straight to PJM Store! (Please note: PJM Store does not provide wood screws).

We provide a wide range of building needs, from lightweight steel, gypsum boards, Spandek roofs, Trimdek, to complete frame accessories.

Toko PJM – Your Complete Solution for Building Needs Contact us at: 0822 2501 3059 Or check the latest promo updates on Instagram: @toko.pjm.bajaringanbali